Material Abundance & Historical Significance

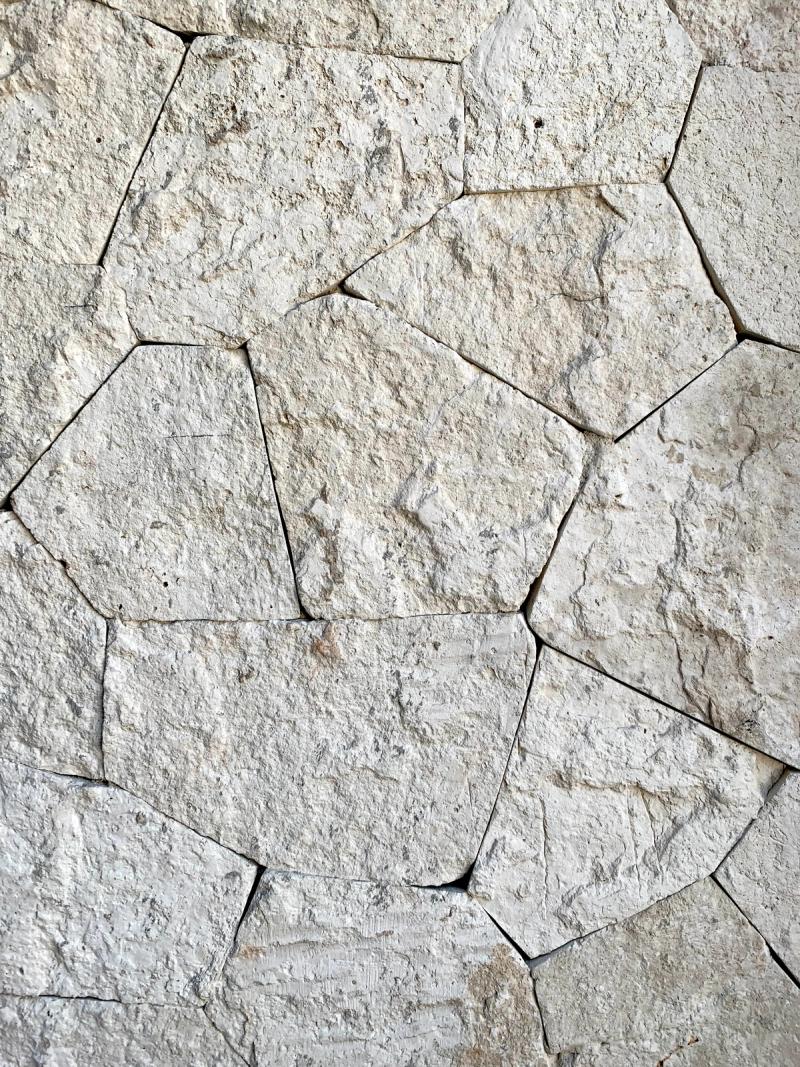

The Yucatan Peninsula is geologically formed of limestone, a sedimentary rock. This abundance has made limestone a readily available and widely used building material throughout the region. The porous nature of limestone also makes it a key element in the peninsula’s unique cenote formations, adding to its cultural and environmental significance.

Limestone has been a primary building material in Quintana Roo since the ancient Mayan civilisation. It is prominently used to construct Tulum's iconic ruins, which showcase limestone's durability and aesthetic appeal. The stone's ability to withstand the test of time is evident in the enduring integrity of these archaeological sites.